Customers often ask about the function of the row of small holes in our scissor forks: is it intended as a unique mark of our products? In fact, these holes are placed there to facilitate the flow of electrophoresis fluid inside the fork.

Electrophoresis is one of the most effective methods for coating metal workpieces. The process of electrophoretic coating involves immersing a conductive substrate in an electrophoretic coating tank filled with a low-concentration dilute mixture, as the anode (or cathode), and the corresponding cathode (or anode) is set in the tank. After the direct current is connected between the two poles for a period of time, a uniform fine and insoluble coating film is deposited on the surface of the object being coated.

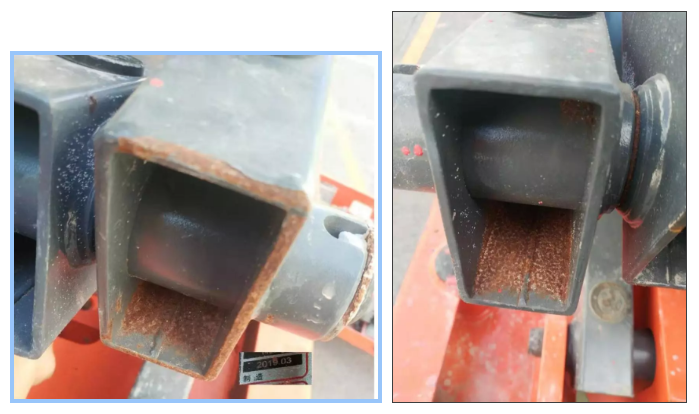

The electrophoresis holes are marked with red circles

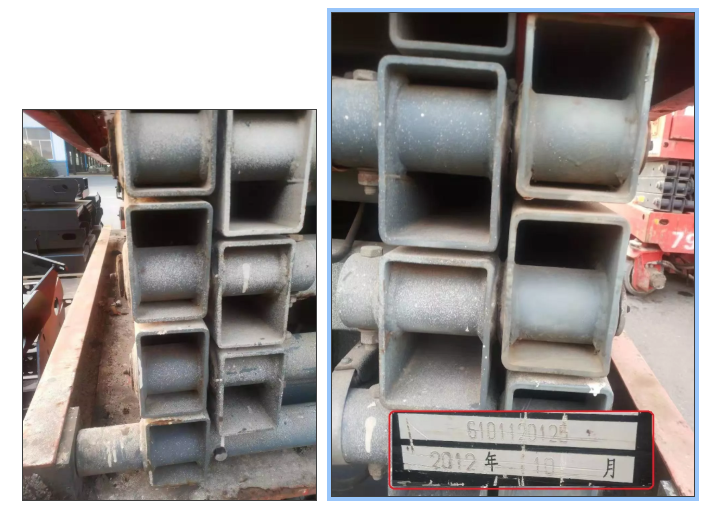

Scissor platform and guardrail electrophoretic primer

Compared with other primers, electrophoretic primer has the following main advantages:

• The electrophoretic coating has a high penetration rate and can penetrate into the interior and gaps of the coating;

• The paint film is uniform, fine and compact;

• Strong corrosion resistance;

• High hardness, impact and wear resistance;

• Corrosion, discoloration and aging resistance;

• Electrophoretic coating has low solvent content, which is conducive to environmental protection and production safety.

The picture above shows a scissor fork coated with conventional paint, manufactured by a certain manufacturer in March 2019. The fork is rusty.

The picture above shows the scissors produced by SINOBOOM in 2012

Most of the structural parts of SINOBOOM’s scissor forks, small parts of boom lifts and thin plate parts, have been through the electrophoretic primer process. This greatly improves the corrosion resistance and rust resistance of these structural parts and maximizes the safety and service life of your equipment.